PRO COMPACT detects and processes analogue variables

By PLANT STAFF

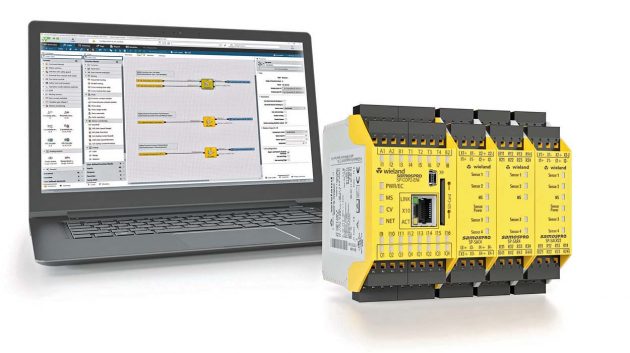

Innovation & Technology Manufacturing analogue Controller manufacturing PRO COMPACT Safety TechnologySafety controller portfolio with three new input modules.

For engineering applications.

PHOTO: WIELAND

Analogue variables such as pressure, flow and temperature must be monitored to ensure safe automation.

Wieland Electric Inc. has extended the samos PRO COMPACT safety controller portfolio with three new input modules (SP-SAC, SP-SAR4, and SP-SACR22) that reliably detect and further process analogue.

These modules are suited for engineering applications in glass, metals or chemicals plus specific areas of mechanical engineering such as conveyor systems, presses and CNC machines

They support sensors with a 0/4-20mA interface as well as temperature-dependent resistors such as Pt/Ni. Values are monitored with the Limit, Range, Relation and Difference function blocks in user programs created with samos PLAN 6, the licence-free programming software.

All inputs and outputs have uniquely assigned visual displays that clearly show operating status at any time and the PLAN 6 software provides a customized report, ensuring documentation complies with all applicable regulations.

Wieland Electric Canada in Oakville, Ont. is a supplier of the German company’s electrical and connection products.