Monitor machine processes in 5G

By PLANT STAFF

Industry Manufacturing 5G advanced technology machinery manufacturingAdvanced technology is in development.

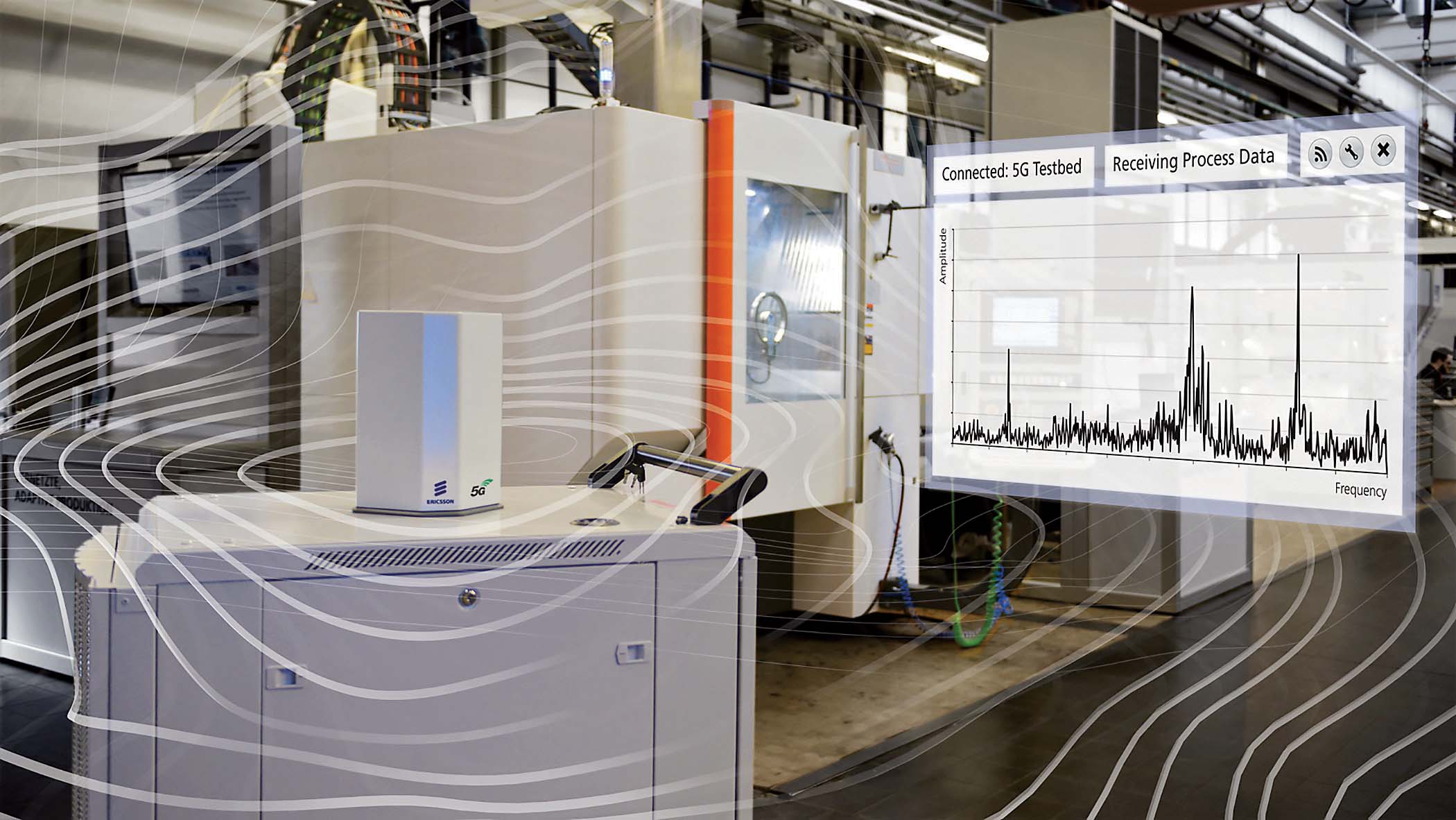

G technology communicates with sensors and machines.

PHOTO: FIPT

A collaboration between Fraunhofer Institute for Production Technology (FIPT) in Germany (www.ipt.fraunhofer.de/en), Ericsson (www.ericsson.com) and GF Machining Solutions (www.gfms.com) has led to a 5G manufacturing process monitoring solution that was presented at the IMTS show in Chicago.

Current work is aimed at the precision requirements of the aerospace industry, but the technology will eventually be found in a range of applications.

When milling parts at high speeds, excessive vibrations lead to surface defects and rework. Real-time process monitoring based on 5G technology (fifth-generation cellular) communicates with sensors and machines to reduce errors.

Ericsson’s mobile communications provides real-time monitoring of sensor vibration data, plus better production control, thus allowing for adjustment of the cutting parameters. As for speed, 5G delivers the data in under one millisecond.

The three companies aim to further develop this type of wireless sensor connection to ensure adaptive control of production processes with extremely short reaction times.

To deliver the power and precision need for such fast reaction, they chose a Mikron MILL P 500 U from GF Machining. It uses highly dynamic direct torque motors as well as a precise gantry with up to 1.7 g acceleration and an accuracy of ±2 µm in the plane.

Digitization of production and the application of 5G technology will undergo additional research and development at the International Center for Networked Adaptive Production (ICNAP) in Aachen, Germany.

This article originally appeared in the October 2018 print issue of PLANT Magazine.