Sandvik launches smart packaging solution

Maryam Farag

Health & Safety Industry News Manufacturing AI Canada environmental impact gender challenges manufacturer manufacturing packaging Sustainability women in manufacturing

Maria Rajabzadeh Namaghi.

Photo: Sandvik Group.

Sandvik Coromant, part of Sandvik Group’s machining solutions division, will launch an optimized packaging solution to level up its operational sustainability.

Developed by R&D Engineer and System Developer, Maria Rajabzadeh Namaghi, as part of Sandvik Coromant’s Automation Platform team, the solution uses artificial intelligence (AI) to determine the smallest possible packaging required to contain a product, reducing costs and CO2 emissions in the process.

Namaghi considered applying a genetic algorithm (GA) using AI. GAs are used to solve optimisation problems and they work by imitating natural selection, and allow the solution to ‘evolve’ until the ideal result is found, in line with Darwin’s theory of evolution.

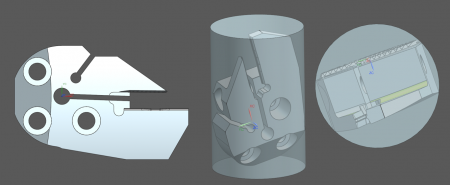

The solution is a package selector application (PSA). The PSA analyzes a 3D CAD model of the product and by identifying the product’s critical points, in combination with the company rules for package selection, the AI algorithm calculates its rotation and recommends the smallest packaging possible.

Photo: Sandvik Group.

“The PSA is incorporated directly to product designers’ CAD programs, so the most suitable packaging for a product can be determined before a physical copy of the tool itself has even been created,” said Namaghi. “The solution completely automates the packaging process, streamlining operations and supporting Sandvik Group’s wider sustainability goals.”

“Optimised packaging selection avoids excessive packaging use, opening up the potential to transport more products at once, increasing shipment capacity,” said Mats W Lundberg, Head of Sustainability, Sandvik Group. “In turn, increased capacity could result in less loads to transport the same number of products, reducing fuel consumption and supporting Sandvik Group’s company-wide target to half its CO2 impact by 2030.”