Pontus files patent application for automated vertical farm harvesting robot

Maryam Farag

Business Operations Economy Industry MRO Electronics Food & Beverage Manufacturing Transportation farm rack system harvesting manufacturer manufacturing Pontus Robot Robotics

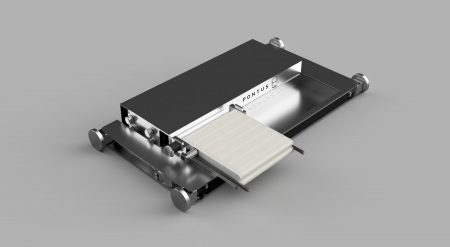

Photo: Pontus Protein Ltd.

Pontus Protein Ltd. has filed an international patent application through the Patent Coordination Treaty with the World Intellectual Property Organization for Pontus’ proprietary harvesting automated robotic vehicle (HARV).

HARV is a vertical farm rack system and automated plant tending and harvesting robot, designed to assist Pontus’ closed environment vertical aquaponics system (CEVAS).

“Talking with the experienced team at Automation Experts (an automation company based in Calgary, Canada), we were able to identify that there was no robot out there that handled everything we needed it to do,” said Steve McArthur, Chief Technology Officer, Pontus. “By harvesting the crop in situ, using HARV, we will reduce the space between the water beds and increase the number of levels, increasing efficiency and the yield. We are beyond excited about pairing HARV with our CEVAS system, as we see CEVAS as a greener, more ecologically sustainable way of producing high nutrition food products.”

CEVAS helps accelerate the growth of Pontus’ water lentils, requiring the plant to be harvested every 24 hours. The HARV technology allows the crop to be automatically harvested daily. HARV will enable Pontus to stack nine levels of vertical farming at its Surrey, British Columbia production facility.

“HARV is more than a mechanical tool for harvesting. It will manage the farm and give us critical insight and data regarding the optimization of the growing environment,” said Stephen Bruce Wong, CEO, Automation Experts. “The robotics in HARV will allow Pontus to eliminate moving parts from the structure thus lowering the cost to build Pontus’ vertical farms as the water beds can be dumb and do not need the technology built into them. It also uses machine learning and artificial intelligence to support all aspects of the growing process.”