Honda producing protective gear for Alliston healthcare workers

By PLANT STAFF

Industry Automotive Manufacturing COVID-19 Face shields honda Innovation manufacturingAutomaker deploys 3D printers and collaborates with Georgian College to produce face shields.

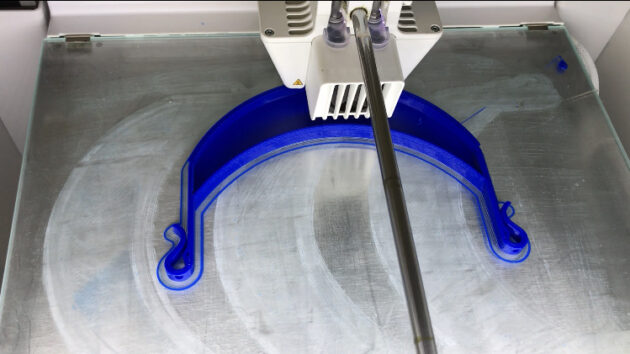

Face shield holder on a 3D printer.

Photo: HCM

ALLISTON, Ont. — Honda of Canada Mfg. (HCM) has partnered with Georgian College to source materials and 3D print face shields for front line healthcare workers.

The auto manufacturer’s Alliston, Ont. site, one of five Honda facilities in North America making equipment for doctors and nurses, is deploying four multiple-duty 3D printers at Plants 1 and 2 to make the protective gear.

“The printers are normally used to make jigs and new model prototype parts, but we realized there was a new way to use them to help front line healthcare workers,” said Ahmed Amir, an associate in the product engineering department.

The visor piece and the attachment feature are made inhouse, while the clear face shield comes from a nearby college.

“We designed the holder piece and for the visor portion, we get roll from a supplier and Georgian College (in Barrie, Ont.) helps us cut it,” said Jim Kerr, a production associate. “We can produce 27 of the hospital style a day, and 95 of the production style (for Honda associates).”

The Honda engineers collaborated with the Stevenson Memorial Hospital in Alliston on the face shield’s requirements, said Terry Grasby, also a production associate. “We make a couple of versions, the other for associates (who wear Honda caps) with a clip arrangement and holder (designed by Kerr).”

The face shields are destined for the hospital, two long-term care facilities (Riverwood Senior Living and Good Samaritan Seniors’ Complex), Matthews House Hospice and My Sister’s Place shelter for women in Alliston.

The engineering team has also come up with a device to relieve the chaffing that results from securing a surgical mask that loops around the ear.

“The ear savers hook onto a plastic piece behind the healthcare worker’s head, taking the load off the back of the ear,” explained Amir.

Printed inhouse, the automaker can produce about 400 of the ear devices daily for hospitals. HCM is working with St. Michael’s Hospital in Toronto and the Trillium Health Partners in Mississauga, Ont. to get feedback.