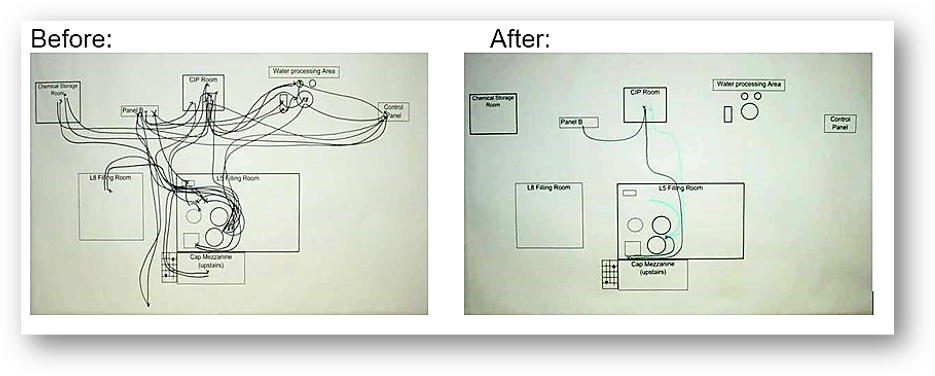

Before and after spaghetti diagrams.

Photo credit: Kunst Solutions

This simple tool delivers powerful results using just pen and paper.

If you really want to continuously improve, first learn how to pause and observe. Of course it’s more natural to observe then jump to a solution, but there’s a risk of missing out on a much larger opportunity.

There are several methodologies that help us pause and observe and even allow us to gather significant data that leads to the creation of a much-improved future state. A very simple but useful tool is the spaghetti diagram. All you need is a sheet of paper, a pen and a time to observe.

First, sketch out a top view of the area to be observed, denoting benches, key pieces of machines and of course storage shelves. Translate the operator’s movements onto the paper diagram, including repetitive walking paths that will show a very solid black line.

A typical process consists of a series of movements. Often people never challenge the location of specific items and adjust their movements to accommodate the process requirement and the location of the items. How many times has a process been improved by doing something as simple as moving a pallet closer to the off-load section of a conveyor? Two steps equals about 1.5 metres, which takes 0.6 seconds. That may not sound like a lot of time but over thousands of steps, it quickly adds up. The objective is to ensure operators are safe, clean and comfortable so minimizing walking will keep our operators fresh longer. Mission accomplished.

The second paradigm to confront is how to change muscle memory, which results from doing a task repetitively for an extended period. Engrained patterns can be changed to reduce wasted time and effort. Here are some tips that will help you create a spaghetti diagram that will lead to improved operator movement:

• Find a perch to observe the entire process (maybe a mezzanine).

• Sketch the observation area. Accuracy is not that important for distance and object size.

• Observe, draw, observe, draw, observe, draw and reflect. Make sure you add all of the anomalies such as replenishing operating supplies.

• Reflect. Go back and observe again with a vision of adjustments in place.

• Adjust.

• Back to the perch and observe and sketch again.

• Compare and calculate.

• Document into a visual work Instruction (a new best practice).

• Wait one or two weeks and again perch, observe and sketch.

• Reflect again. What reverted back and which changes stuck?

Use a spaghetti diagram to design a new process and include your proposed task times, delays and moves. It will help you visualize and balance processes.

___________

Richard Kunst is president and CEO of Cambridge, Ont.-based Kunst Solutions Corp., which helps companies become more agile, develop evolutionary management and implement lean solutions. Visit www.kunstsolutions.com. E-mail rkunst@kunstartofsolutions.com.