Mitsubishi selects Emerson for hydrogen hub

Monica Ferguson

Cleantech Canada Energy Advanced Clean Energy Storage automation software green hydrogen hydrogen hub increase safety Mitsubishi Power storage facility

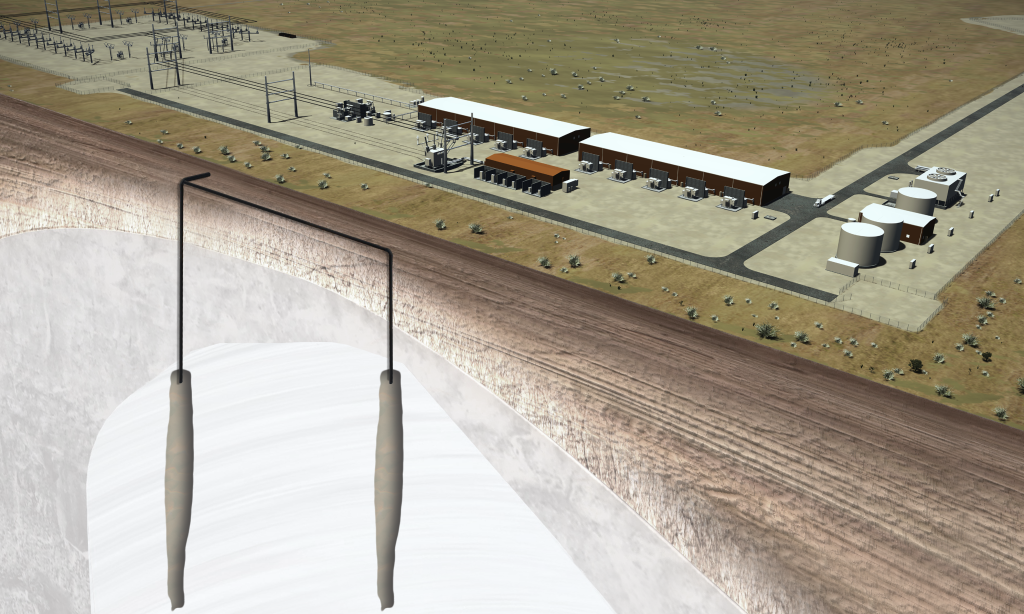

Photo: Mitsubishi Power.

Mitsubishi Power Americas selected Emerson to automate the world’s largest green hydrogen production and storage facility. The hub will help integrate renewable energy by producing and storing green hydrogen for long duration energy storage. Mitsubishi Power will use Emerson’s hydrogen production experience and automation software to increase safety, decrease costs and simplify maintenance across the life cycle of the facility.

The Advanced Clean Energy Storage hub will use renewable electricity to power electrolyzers to produce green hydrogen. The produced hydrogen will be stored underground in salt caverns so that it can be dispatched when required to generate clean electricity from hydrogen-fueled turbines, which will help stabilize the grid with sustainable sources and create a new pathway to decarbonization of the western United States.

“Generating, storing and transmitting electricity with zero carbon emissions is critical to meeting the world’s sustainable power generation needs,” said Michael Ducker, senior vice-president of hydrogen infrastructure, Mitsubishi Power. “Emerson’s hydrogen expertise and digitally connected architecture design will help shorten time to start up, while also developing a safe, reliable and easily scalable transmission system to meet our goals for renewable energy production and storage.”

The hub will convert renewable energy through the 220-megawatt electrolyzer bank to produce up to 100 tons of green hydrogen per day. The facility will have storage for 300 gigawatt hours of energy in two salt caverns. In comparison, the battery storage capacity across the United States is 2-GWh via lithium-ion batteries. The Advanced Clean Energy Storage hub has space for up to 100 caverns.